Any restaurant that sells soft serve ice cream, for example, needs a chiller to keep the ice cream at a constant temperature to maintain its consistency. Unlike a refrigeration unit which wastes the heat that its motor produces while cooling the inside; a chiller uses a heat exchanger to cool equipment by circulating liquid. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

At Tark Thermal Solutions, we position ourselves as a dedicated partner in advanced cooling technology, delivering liquid chillers that support precise temperature control across demanding applications. We design and build our systems with a focus on reliability, thermal stability, and energy efficiency, tailoring each unit so it performs consistently in environments where process accuracy...

We are ChillX Chillers, and we take pride in engineering and manufacturing reliable, high-performance chillers designed to meet the cooling needs of businesses across a wide range of industries. Our focus has always been on combining innovation, energy efficiency, and durability, which is why our chillers are trusted for everything from process cooling and manufacturing applications to...

More Food Processing Chiller Manufacturers

Water chillers are the most common type of chilling equipment found in most food and beverage businesses. These units circulate water through a heat exchanger to cool whatever is contained in them and maintain a constant temperature. An exterior control system allows operators to manage the unit and set the desired temperature. This kind of technology is used to cool soft drinks, baking mixes, wine, sauces, soups and more.

Large food processing chillers can be found in factories where food is being prepared for packaging and shipment to grocery stores and distribution centers. A chiller is important during the wine making process to develop a consistent taste and create the best possible product. Too much variation in temperature during fermentation could lead to a ruined batch, particularly if the temperature becomes too warm.

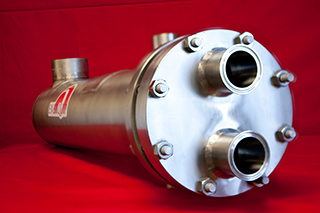

A food processing chiller is usually made using stainless steel so that it can be easily wiped down and kept clean to ensure that food and safety standards for cleanliness are maintained at all times. In food manufacturing facilities, a chiller only represents a small fraction of the necessary processing equipment, but it is essential to the reliability and precision of the final product.

Dairy processing facilities use large chillers to keep milk from spoiling before it is bottled, and any cafeteria that has milk on tap will store the milk in a chilling machine that keeps it at a steady temperature before it is consumed.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services