A water chiller is a refrigeration system that uses water as a refrigerant for the removal of heat to control for cooling a process or equipment. In the completion of products or production operations, it is necessary to remove heat to maintain the quality of a product or avoid damage to equipment. Water chillers efficiently remove heat from equipment and use a heat exchanger to transfer the heat into the air. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

We have manufacturing experiences dating back to 1952 and over the years Glen Dimplex Thermal Solutions has grown in an international provider of high quality chillers. We operate out of an ISO-9001 facility and our teams work hard to bring you the very best chillers. Our teams will even work with you to create a custom chiller. Please give us a call today!

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Water Chiller Manufacturers

A key factor for a water chiller is the pumping system that circulates the cooled water or a glycol and water solution. Circulating water removes heat and carries it back to the chiller for treatment. During the process, heat is transferred from the heated water to the chiller in a continuous cycle.

The cooling process provided by a water chiller is an important part of injection molding, tool and die cutting, food and beverage processing, chemical industry processes, lasers, and machine tooling. Heat is a common byproduct of industrial processes that needs to be removed for the protection of a process or to maintain efficiency. Water chillers provide consistent temperature and pressure to ensure the safety and effectiveness of equipment and avoid equipment failure.

How a Water Chiller Works

The four main components of a water chiller are the evaporator, expansion valve, condenser, and compressor. During the chilling process, water constantly cycles through these four elements where it absorbs heat and releases it. A key to the process is refrigerant, which changes from a liquid to a gas as it passes through the four parts of the water chiller unit.

Compressor

The function of the compressor is to create a pressure difference that moves the refrigerant through the system. Compressors come in various shapes and sizes and include centrifugal, screw, scroll, and reciprocating. Regardless of the variations of compressors, all types are designed to perform the same function.

The compressor is located between the condenser and evaporator and is attached to an electric motor that provides power. The motor of a compressor may be installed internally or externally depending on the design of a water chiller.

Condenser

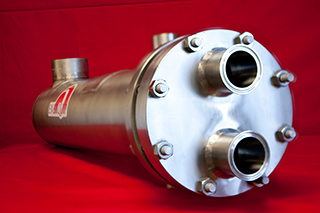

The condenser removes the absorbed heat from the refrigerant that it picked up in the evaporator. With water type condensers, the water is cycled continuously between the cooling tower, where the heat is released, and the condenser. The refrigerant is contained in a set of pipes against which the water that collects the heat passes.

Expansion Valve

The expansion valve receives the refrigerant that is under high pressure from the condenser. The pressure of the refrigerant has to be lowered before it can move on to the evaporator, which is the job of the expansion valve. As the refrigerant passes through the expansion valve, its pressure lowers to a point such that it can be vaporized in the evaporator. The expansion valve controls the flow of refrigerant according to the load on the evaporator.

There are several types of expansion valves that include capillary tubes, thermostatic, low side float valves, and constant pressure ones.

Evaporator

The evaporator collects the heat that it receives from the water that has cooled the process and moves it into the refrigerant such that it can be removed through the cooling tower. The water cools as heat is extracted by the refrigerant and is pumped back to the process to continue the cooling cycle.

Power Unit

The power unit supplies power to a water chiller. It can be mounted on the chiller or on a wall near the chiller. The power unit controls the flow of power to the chiller and has a starter, circuit breaker, speed controller, and monitoring device.

Control Unit

The control unit monitors the performance of the chiller and makes it possible to adjust various aspects of the chiller process. It has an alarm system that shuts down the system when there are errors or problems during operation. Modern water chillers have a building management system (BMS) that makes it possible to send data to the control unit in regard to temperature, pressure, and on and off status.

An essential part of the performance of a water chiller control unit is to gather data and critical information from all aspects of the chiller system. The data is centralized and examined for trends and helps in making decisions regarding chiller operation.

Benefits of a Water Chiller

Chillers are an essential part of industrial operations and are used to remove heat to create cold conditions for processes and equipment. The most common types of chillers are air cooled and water cooled where an air cooled chiller removes heat using fans while a water cooled chiller uses water. Both types have their benefits that need to be considered when making the decision to purchase.

The benefits of a water chillers are:

Long Working Life

Water chillers are housed inside a building away from the elements, a factor that gives them a long working life. The fact that water chillers remain inside further enhances their use since they can be used by companies that do not have access to outdoor space.

Quiet

Water chillers work quieter than air chillers due to the fact they do not have the ducts and vents that air chillers do. The flow of water does not create the expansion and contraction noise that air does, which is important for the use of chillers in hospitals and schools.

Efficiency

With industrial operations and applications, efficiency is important since it guarantees the quality of a product and cost savings. The process that water chillers use to transfer and remove heat is efficient and energy saving. Water is continuously used and recycled removing the need for depending on the city water supply.

Equipment Protection

Water chillers are designed to protect valuable equipment, which cuts down on repairs and maintenance. They operate year round, regardless of the weather, and are dependable in all kinds of environments. Water chillers eliminate heat from spot welders, injection molding, and laser cutting processes. They can be used with any application that requires the limitation and removal of heat.

Choosing the Proper Water Chillers Manufacturer

To make sure you have the most productive outcome when purchasing water chillers from a water chiller manufacturer, it is important to compare at least 4 to 5 manufacturers using our water chiller directory. Each water chiller manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information. Review each water chiller business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple water chiller businesses with the same quote.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services