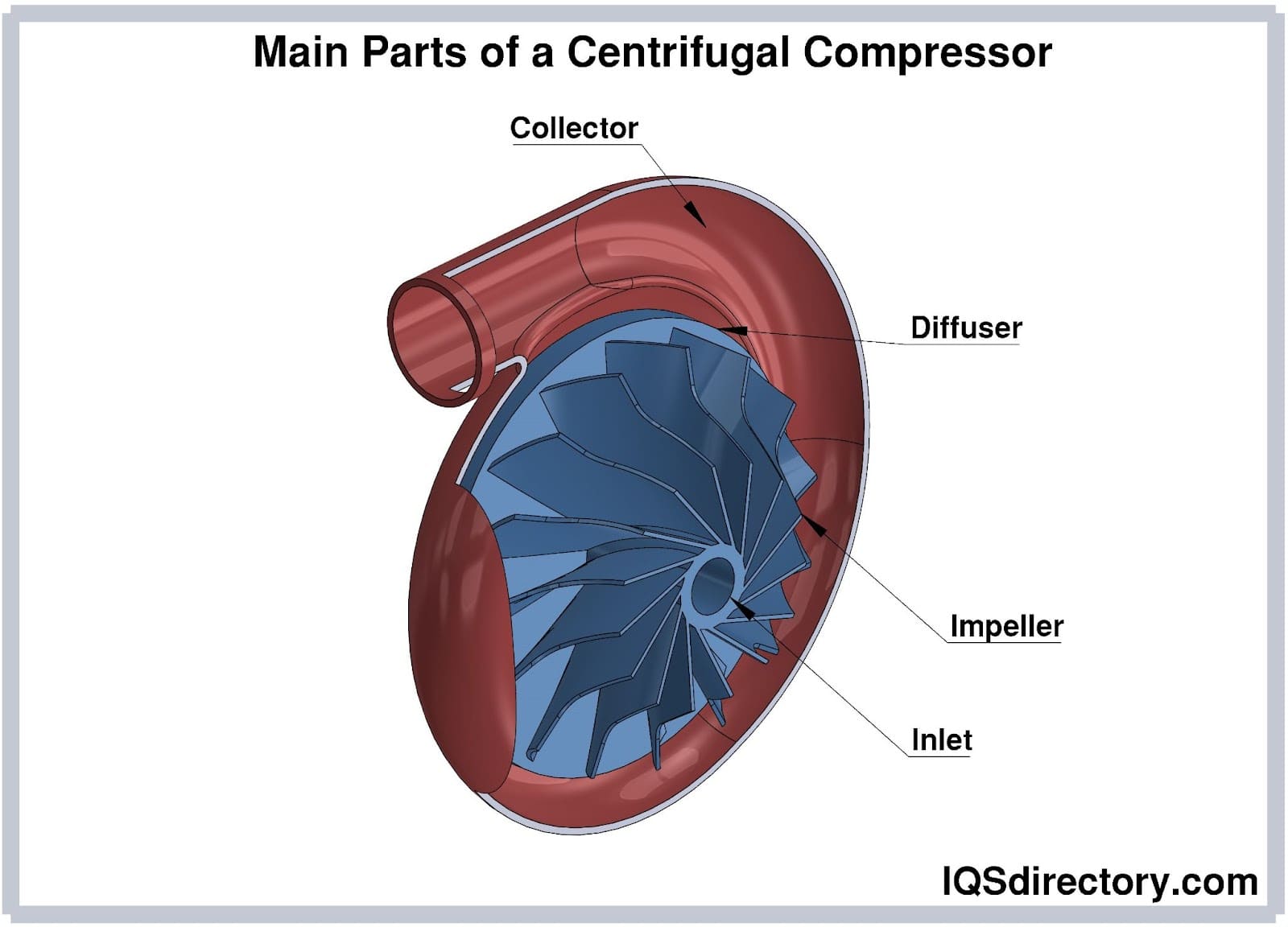

A centrifugal chiller uses an impeller wheel to create pressure in the refrigerant gas by the velocity of its rotation. When the refrigerant enters the centrifugal compressor, its pressure must be raised to enter the condenser. The rotation of the impeller in a centrifugal compressor creates the necessary driving force to increase the pressure of the gasses from the evaporator. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Centrifugal Chiller Manufacturers

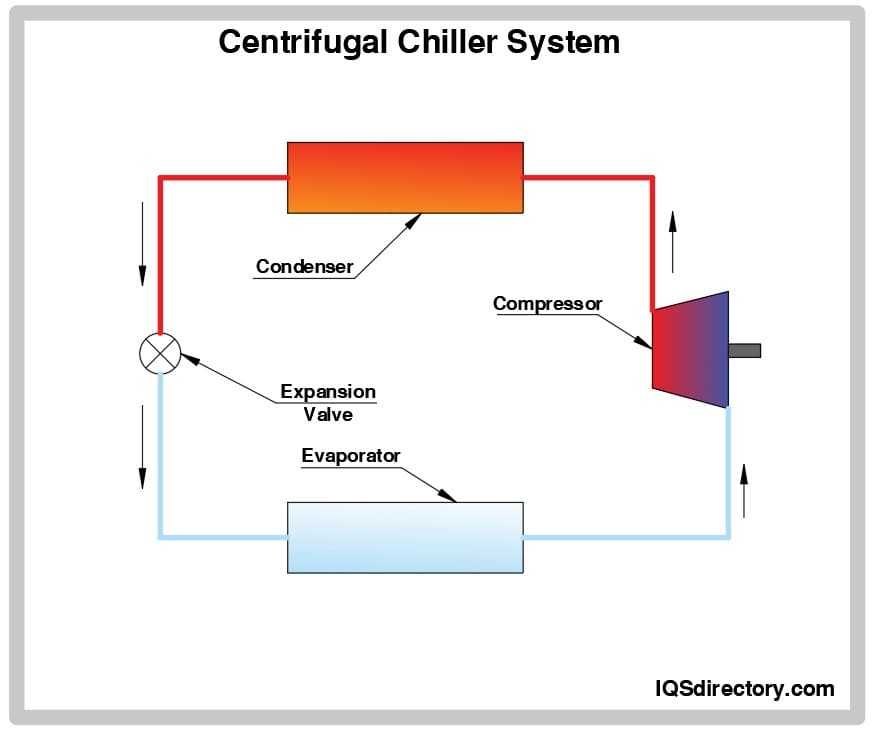

In a chiller system, the compressor is placed between the evaporator and the condenser. It is responsible for increasing the pressure in the refrigerant gasses, while the evaporator changes the liquid refrigerant into gas. Then, it passes it to the compressor, which increases the temperature and pressure of the created gas before it is passed on to the condenser.

How a Centrifugal Chiller Works

A centrifugal chiller uses a vapor compression cycle to chill water and remove heat from the water and the compressor.

Evaporator

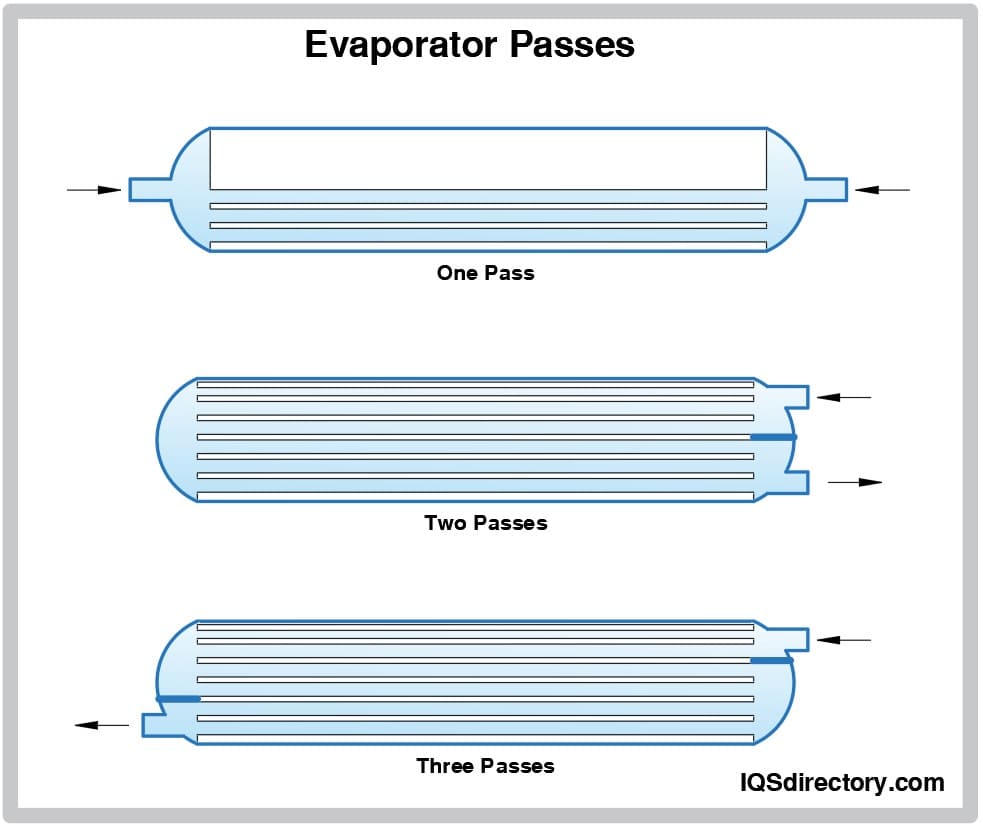

The evaporator is a heat exchanger that removes heat from chilled water. The collected heat is used to superheat the refrigerant to change it from a liquid to a gas. The water in a chiller system collects heat, which has to be removed as part of the chiller cycle. Evaporators are tightly sealed to ensure their efficiency and that they do not allow the heat in the water to escape. In most cases, the insulation material is a vinyl nitrate polymer that is 0.75 of an inch (20 mm) thick.

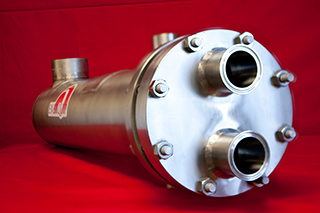

Evaporators have a shell and tube construction with the tubes encased inside the shell. The shell holds the refrigerant while the tubes contain the water to be cooled. In all chiller, the water in the tubes and the refrigerant never come in contact. The refrigerant enters the evaporator as a liquid through the bottom of the expansion valve. Refrigerants have a very low boiling point. However, the heat from the warm chilled water causes the refrigerant to boil and become a vapor.

The number of passes describes the type of an evaporator, which can be one, two, or more. With a one-pass evaporator, the water passes through one time and into the water box. When an evaporator has multiple passes, the water passes through the evaporator, turns around, and goes back through it two or more times.

Centrifugal Compressor

The refrigerant gas created by the evaporator passes into the centrifugal compressor with four main parts: the inlet, impeller, diffuser, and collector. In the centrifugal compressor, the rotation of the impeller builds up kinetic energy to expel the gasses into the condenser.

Inlet

The inlet is a pipe where the gas from the evaporator enters the compressor. The different types of inlets include openings, valves, or channels. They direct the flow in the proper direction into the compressor.

Impeller

In a centrifugal compressor, the impeller is the critical component that generates the necessary centrifugal force. It contains a rotor with angled vanes that spin to raise the energy in the gasses.

Diffuser

As the impeller spins, it throws the gasses outward where they hit the diffuser, which takes the kinetic energy from the rapid rotation and slows the velocity of the gasses. The decrease in speed increases the pressure of the gasses. There are several ways that the diffuser slows the gasses' motion, including channels and wedged vanes.

Collector

The collector is an empty chamber where the flow from the diffuser is collected. It has the shape of circular spiral arcs that are designed such that they can capture the complete radius of the impeller and diffuser. Certain forms of collectors, much like inlets, have valves and other features.

Condenser

The condenser has a function similar to that of the evaporator in that it is a heat exchanger. In the condenser, the liquid refrigerant that has been changed into a gas is returned to its liquid form. As the gas moves through the tubes of the condenser, its heat is removed and placed in water that flows around the tubes. Finally, the collected heat is released using a cooling tower in a water chiller or a set of fans in an air chiller.

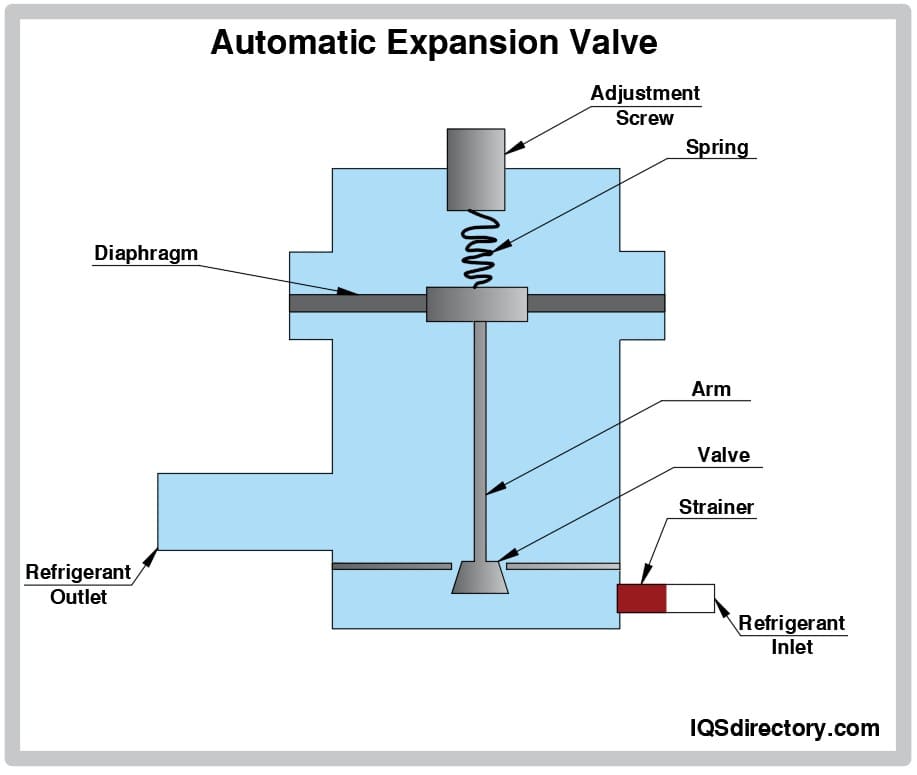

Expansion Valve

Expansion valves control the flow of the refrigerant and help change the liquid refrigerant to gas by slowly releasing small amounts of liquid into the evaporator. The configuration and types of expansion valves vary from a simple opening to a complex electronic expansion valves.

When the newly created liquid moves from the condenser back to the evaporator, it must have its pressure change from the high pressure of the condenser to the low pressure required by the evaporator. The expansion valve is designed to maintain the pressure differential between the condenser and evaporator. For the refrigerant to be able to absorb heat in the evaporator, it has to be at low pressure.

Centrifugal Chiller Maintenance

Centrifugal maintenance tasks:

- Oil Change

- Acid Removal from Compressor Discharge

- R134a Refrigerant Exclusively for Centrifugal Chillers

- Metal Build-Up in the Compressor

- Change Oil Filters

- Regular Check of Compressor Oil

- Check for Leaks in “O” Rings and Shaft Seals

Choosing the Correct Centrifugal Chiller Manufacturer

To make sure you have the most beneficial outcome when purchasing a centrifugal chiller from a centrifugal chiller manufacturer, it is important to compare several companies using our directory of centrifugal chiller manufacturers. Each company has a business profile page highlighting their capabilities and areas of experience, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each centrifugal chiller business website using our patented website previewer to get an idea of what each company specializes in. Then, use our simple RFQ form to contact multiple centrifugal chiller businesses with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services