Liquid chillers are devices that are used to remove heat from a liquid, which can then be used for various purposes. They are widely used in different industries and applications, such as in HVAC systems, data centers, industrial processes, medical equipment, and food processing. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Liquid Chiller Manufacturers

Components of Liquid Chillers

A liquid chiller consists of a compressor, an evaporator, a condenser, and an expansion valve. The compressor circulates the refrigerant and compresses it into a high-pressure gas. The high-pressure gas is then sent to the condenser, where it releases the heat it has absorbed from the liquid, causing it to condense into a liquid. The liquid then passes through the expansion valve, where it is converted into a low-pressure liquid and sent to the evaporator. In the evaporator, the refrigerant absorbs heat from the liquid, causing it to evaporate. The refrigerant then returns to the compressor, and the cycle starts again.

Variations of Liquid Chillers

There are several variations of liquid chillers, each with its own design or component differences. For example, air-cooled chillers use air to remove the heat from the refrigerant, while water-cooled chillers use water. Portable chillers are self-contained units that can be moved from one location to another, while central chillers are used in large buildings or industrial processes. Other variations include absorption chillers, which use a heat source to drive the cooling process, and centrifugal chillers, which use a centrifugal compressor to circulate the refrigerant.

Materials Used to Construct Liquid Chillers

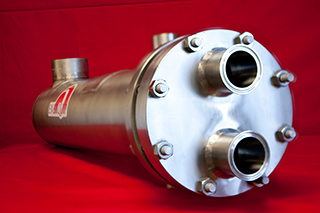

Liquid chillers can be made from various materials, depending on the specific application. For example, stainless steel is often used in food processing and medical equipment, as it is easy to clean and does not corrode. Aluminum is a popular choice for air-cooled chillers, as it is lightweight and has good heat transfer properties. Copper is used in water-cooled chillers because of its excellent thermal conductivity.

Considerations Regarding Liquid Chillers

One of the main considerations regarding liquid chillers is their energy consumption. They require a significant amount of energy to operate, which can result in high operating costs. Additionally, they require regular maintenance to ensure that they operate efficiently and do not break down.

Benefits of Liquid Chillers

Despite their limitations, liquid chillers offer several benefits. They are highly efficient at removing heat from liquids, which is essential in many industries and applications. They are also very versatile, as they can be used with different types of liquids and in a wide range of temperatures. Additionally, they offer precise temperature control, which is essential in many processes.

Applications of Liquid Chillers

Due to these, and other, benefits liquid chillers are used in many applications, including:

HVAC Systems in Buildings

Liquid chillers are widely used in heating, ventilation, and air conditioning (HVAC) systems in buildings. They are used to cool the air in large buildings and maintain a comfortable indoor temperature for occupants. The chillers can be installed either as a central unit or as a distributed system, depending on the size of the building. The chiller can use either water or air as a cooling medium, depending on the specific application.

Industrial Processes

Liquid chillers are extensively used in various industrial processes that require precise temperature control. For example, they are used in plastic molding to cool the molds and reduce cycle times. They are also used in laser cutting to cool the cutting head and reduce thermal distortion. In chemical manufacturing, liquid chillers are used to cool reaction vessels and maintain the temperature within a specific range. They are also used in the pharmaceutical industry to cool reaction vessels, and freeze-drying chambers.

Medical Equipment

Medical equipment, such as magnetic resonance imaging (MRI) machines, require precise temperature control to operate correctly. Liquid chillers are used to cool the magnets and ensure that they operate at the required temperature. Chillers are also used in cancer treatment equipment, such as radiation therapy machines.

Data Centers

Data centers generate a significant amount of heat due to the high density of servers. Liquid chillers are used to cool the servers and ensure that they operate at a safe temperature. Chillers can be installed either as an external system or an internal system, depending on the specific application.

Food and Beverage Processing

Liquid chillers are also widely used in the food and beverage processing industry to cool or freeze food products. For example, they are used in ice cream production to freeze the mixture, in brewing to cool the wort, and in the meat processing industry to cool or freeze meat products.

Recreational Facilities

Likewise, liquid chillers are used in recreational facilities, such as ice rinks, to maintain the ice at the required temperature. Chillers can also be used in indoor ski resorts to maintain the snow at the required temperature.

Solar Power Generation

Additionally, liquid chillers are used in solar power generation to cool the solar panels and maintain the efficiency of the system. They are used to maintain the temperature of the panels within a specific range and prevent damage due to overheating.

Chemical Processing

Furthermore, liquid chillers are used in chemical processing to cool the process fluids and maintain the temperature within a specific range. They are also used to cool heat exchangers, reactors, and distillation columns.

Beverage Dispensing

Liquid chillers are also used in beverage dispensing systems, such as soda fountains, to chill the beverage and maintain it at the required temperature. They are also used in beer dispensing systems to cool the beer and maintain it at the correct temperature.

Marine Applications

Finally, liquid chillers are used in marine applications, such as on-board cooling systems for boats and ships. Here, they are used to cool the engine and maintain it at the required temperature, which can improve the efficiency and reliability of the engine. Liquid chillers can also be used in on-board cooling systems to provide cooling for people or other things on boats.

Choosing the Correct Liquid Chiller Manufacturer

To ensure you have the most productive outcome when purchasing a liquid chiller from a liquid chiller manufacturer, it is important to compare several companies using our directory of liquid chiller manufacturers. Each liquid chiller manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each liquid chiller business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple liquid chiller companies with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services