Recirculating chillers create high-pressure flow using a coolant fluid or refrigerant to lower temperatures to meet application specifications. They have a closed loop system that uses the same fluid to complete the cooling process. Recirculating chillers use air or water for heat dissipation and are a cost-effective and efficient cooling process. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Recirculating Chiller Manufacturers

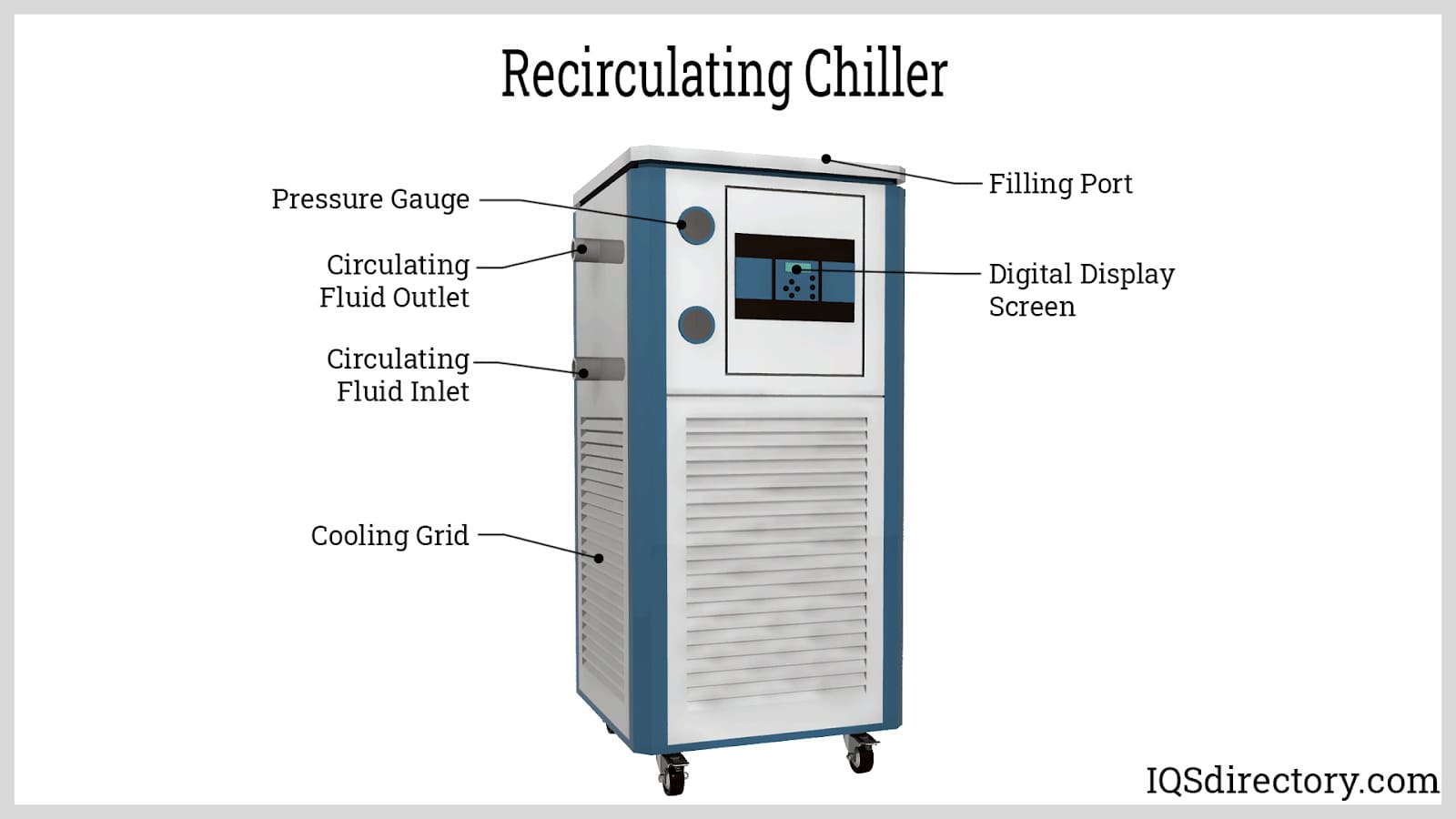

A key characteristic of recirculating chillers is their ability to provide precise and continuous temperature control through the recirculation of the coolant. They are compact, self-contained cooling units that are exceptionally resilient and reliable. The purpose of recirculating chillers is to eliminate mechanical and electrical heat by pulling air from a process or space and removing or releasing the heat in the air. Modern manufacturing processes require precise thermal control to ensure the success of a process. Recirculating chillers provide the instrumentation and control necessary to achieve successful and positive results.

Recirculating Chiller Process

A recirculating chiller uses coolant circulation and high-pressure flow to enhance and speed up the heat removal and cooling processes. They have the same components as all types of chillers: a compressor, condenser, expansion valve, and evaporator.

Evaporator

The cooling process for a recirculating chiller begins with the refrigerant entering the evaporator, where it is transformed from a liquid to gas using the heat extracted from the cooling process. The gas created by the evaporator has a very low pressure that must be changed to enter the condenser. Several different designs of evaporators are used by recirculating chillers and include coil evaporators, which are the most commonly used.

Compressor

Compressors for recirculating chillers are normally scroll or screw, which are capable of fitting a recirculating chiller's design. The purpose of the compressor is to take the low-pressure and low-temperature refrigerant from the evaporator and raise them to meet the requirements of the condenser.

- Scroll Compressors – Scroll compressors have two spiral disks placed over one another. One of the disks is static, while the other rotates around the static disk. During the disk's rotation, the refrigerant gets caught in pockets of air, where its pressure and temperature increase.

- Screw Compressors – Screw compressors have rotating helical screws, male and female, that mesh together to compress the refrigerant gas before sending it on to the condenser.

Condenser

The condenser is where the heat from the process of the compressor is dissipated. In the condenser, heat is released from the refrigerant and removed by water or air circulation. In most recirculating chillers, the removal process is completed by a fan or blower. Removal of the heat decreases the temperature of the refrigerant, which causes it to return to liquid form. The recirculation process begins when the liquified refrigerant leaves the condenser. The refrigerant remains in the system to be returned to the process through the expansion valve between the condenser and evaporator.

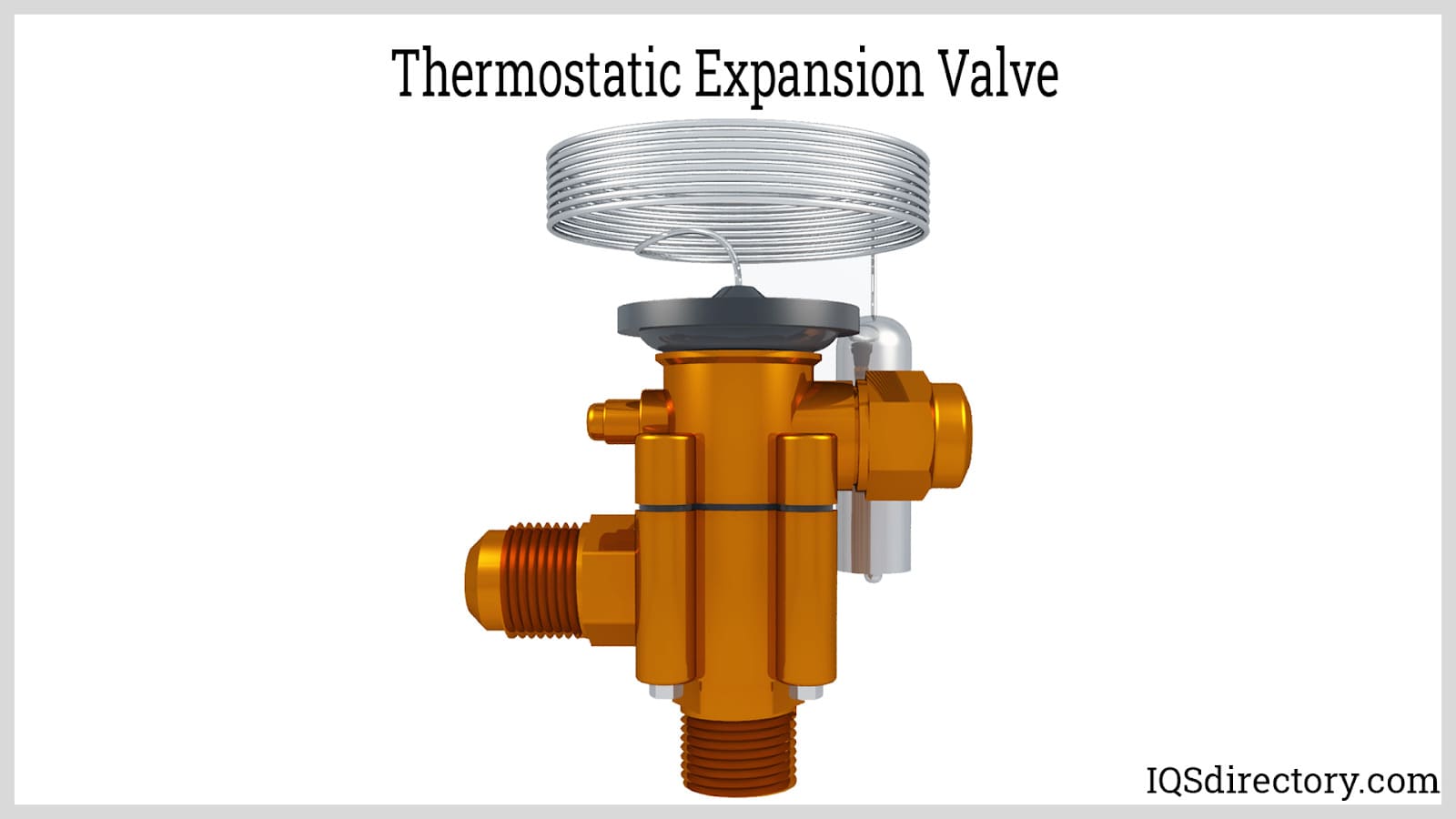

Expansion Valve

As with other parts of a recirculating chiller, there are several types of expansion valves, all designed to control the flow, pressure, and temperature of the refrigerant. The expansion valve slowly releases the refrigerant at low pressure and temperature into the evaporator to restart the cooling process. Normally, recirculating chillers have thermostatic expansion valves that can be regulated by adjusting the temperature at which it will release the refrigerant. They are highly reliable and react quickly to adjustments.

Benefits of Recirculating Chillers

Recirculating chillers are highly efficient, easy to install, and exceptionally accurate cooling devices. They are widely used in many applications due to their economical operation and reliable performance. In addition, their ability to rapidly remove heat from an operation, process, or environment has made them one of the more popular types of chilling units.

- Reduced Waste – Methods that have been used for years to cool processes have been water, ice, and nitrogen oxide. Although they were effective, they required a great deal of wasted water that could not be reused. Recirculating chillers have eliminated the old cooling methods and replaced them with a process far exceeding the demands of any cooling needs.

- Efficiency – Of all of the characteristics of industrial devices, efficiency is the hallmark of a device's performance. The closed loop design of recirculating chillers makes them one of the most efficient types of chillers. Their ability to quickly produce the necessary temperatures reliably makes them an ideal cooling tool. Once a recirculating chiller is charged and operating, it provides constant and consistent cooling without fluctuation or variance.

- Cost – Along with the need for efficiency is the need for cost savings, which has become a major concern in today's business environment. Although the initial cost of a recirculating chiller may be high, it can be recouped through a recirculating chiller's longevity. Once a recirculating chiller is in operation, it requires little maintenance, offers exceptional performance, and seldom needs fluids, components, or parts replaced.

Factors to Consider When Choosing a Recirculating Chiller

- Necessary Temperature Range – Recirculating chillers can reach a set point of -130 °F (-90 °C) and act as a heater maintaining a temperature of 302 °F (150 °C).

- Cooling Capacity – The chiller should match the cooling capacity needed for the application.

- Chiller Size – For a recirculating chiller to provide optimum performance, its capacity should match the application for which it is being used.

- Energy Use – For proper use, a recirculating chiller should have a flow rate that ensures that it provides accurate temperatures without using excess energy.

Choosing the Right Recirculating Chiller Business

To guarantee the most positive result when purchasing a recirculating chiller from a recirculating chiller manufacturer, it is important to compare several companies using our directory of recirculating chiller companies. Each recirculating chiller manufacturer has a business profile page highlighting their their areas of experience and capabilities, and a contact form to directly communicate with the company for more information or request a quote, Review each recirculating chiller company website using our patented website previewer for an understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services