Absorption chillers are quiet, vibration free, reliable, low maintenance and don’t use any CFC gases. Because they are driven primarily by heat energy instead of mechanical energy, they are used in industrial manufacturing plants that use boilers or have access to wasted heat from different machinery and processes. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Absorption Chiller Manufacturers

The heat source may be solar, gas, water or bromide and steam. In this way they reduce electric peaks in a building's electric load, cutting costs during the hottest times of the year. They may act as the sole cooling system, or work as part of an integrated cooling and heating system. Although more complex, absorption chillers act similarly to some residential refrigerators, which have a gas flame at the bottom and ice cubes at the top.

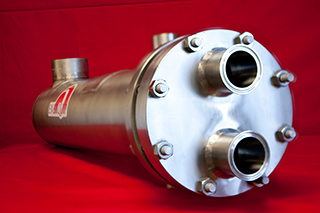

Components of absorption chillers must be integrated closely. The compressor, condenser and evaporator equipment are all contained in a single area within the facility. The process begins when a refrigerant, usually ammonia, carbon dioxide, sulfur dioxide, alcohol, brine or methane, is put under pressure, causing heat to build up in the compressor.

The liquid is then converted to vapor, and moved into the condenser. The heat leaves, causing the gas to turn to liquid. The cooled liquid then travels to the evaporator, and turns into gas, pulling heat from a liquid coolant or from the air. The chilled air or fluid is then pumped into the process or facility, effectively cooling it down to a desired temperature. The pump is the only electrically-powered component.

Absorption chillers may be direct, meaning the heat source is gas or fuel that is burned in the unit, or indirect, using steam or other transfer fluids to bring heat from other sources like the boiler or various heat-generating industrial processes. The system may also use both the indirect and direct heat-drawing methods at the same time.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services