Most brewery chillers require glycol, which is a food grade anti-freeze, because they run at temperatures below 32°F, hence, they are also called brewery glycol chillers. Glycol chillers are installed outdoors in an all in one type design. There are two main kinds of brewery glycol chillers, the modular brewery chiller and the split brewery chiller. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Brewery Chiller Manufacturers

The modular brewery chiller is used as a booster chiller if the brewery already has a tank and pump, or if the existing chiller is not functioning adequately for the needs of the brewery. This kind of chiller has no tank or pump. The split brewery chiller can be used if the chiller unit is on the roof. Because it is used when the tank or pump or heat exchanger are in separate cabinets, it is possible for this chiller to be located indoors, or at an easily accessible location for maintenance. This is basically an indoor chiller with an outdoor condensing unit.

Most brewery chillers come with remote control panels for indoor installation and for easy operation. Before you buy a brewery chiller, make sure to purchase a system that would be suitable for your applications, making sure the chiller being purchased can operate at the temperatures you require. Also, check the power requirements of the chiller to match the power supply of the building in which it is to be used.

Brewery chillers can come in a variety of configurations, some offered as a packaged system and others as separate components. That means certain chiller configurations may work better for a given application depending on the amount of available space. Lastly, it is not advisable to purchase a brewery chiller that has been in use for more that 10 years due to the reduced reliability of the system. With these considerations in mind, you can find a brewery chiller that satisfies your application requirements and fits within your budget.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

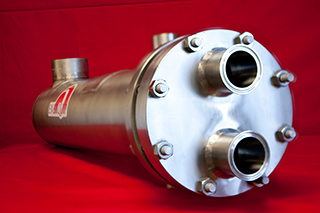

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services