The distinguishing feature of a screw chiller is its two helical slot rotors. They are convex and concave, with male lobes and female gullies that mesh together to compress refrigerant gasses. As the rotors turn, the refrigerant gas is compressed by volume reduction and transformed into a vapor to pass onto the condenser. Read More…

Our customers know they can trust us for the ultimate in quality, affordability, and flexibility. If you want a fully customized solution for your chillers, we can help! We work hard to create the best solution for each of our customers, because we know that if you are not happy, we are not happy! You can learn more about our services by visiting our website or giving us a call today!

Industry leading, eco- friendly technology from Delta T Systems is setting the pace with energy efficient portable or packaged chiller systems and temperature control units. Our expansive standard product line has been successfully applied in a broad variety of industries for over 30 years. And for applications that require unique features or functionality, our custom design team has the know-how ...

Since 1969, Thermal Care has been a leading manufacturer of portable and central chillers in air cooled, water cooled, and remote condenser models. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in meeting the specific needs of our customers by offering both standard and custom designed industrial process cooling...

Dimplex Thermal Solutions, based in Kalamazoo, Mich., and home of Koolant Koolers, has been manufacturing water, air, and glycol chillers since 1952. Since that time Dimplex has expanded it’s product offering to include industrial cooling for: Machine Tooling, Food Processing and Packaging, Medical Diagnostic Imaging, Laser Cutting, Manufacturing Processes and more. Dimplex is known for their...

Thermonics® offers a range of process chillers for low (-40°C) and ultra-low (-100°C) temperature cooling. Products include air- and water-cooled chillers, and cryogenic chillers for cooling gasses and fluids. Chillers are compatible with a variety of heat transfer fluids delivering cooling capacities up to 25kW at -90°C, satisfying demands for industrial and mil/aero applications. We are a...

EcoChillers, Inc. provides eco-friendly chillers for the manufacturing industry. We work to make sure that you have a high-quality customer service experience. Our products are sure to help solve all of your chiller needs. We have an elite team of dedicated and seasoned professionals who make sure that you have top of the line service with world class parts. We devote extra attention to making...

Founded in 1970, we remain focused on the design, manufacture and sales of industrial chillers and temperature controllers, with a long and vast experience in high accuracy systems. The wide range of the products permits to satisfy all specific demands of all kinds and sizes of industries. Frigosystem can structure their offer with tailor-made plants and proposals, always oriented to efficiency...

More Screw Chiller Manufacturers

The distinguishing feature of a screw chiller is its two helical slot rotors. They are convex and concave, with male lobes and female gullies that mesh together to compress refrigerant gasses. As the rotors turn, the refrigerant gas is compressed by volume reduction and transformed into a vapor to pass onto the condenser. Sliders in the compressor regulate the length of the compression path, all of which occurs in a linear direction.

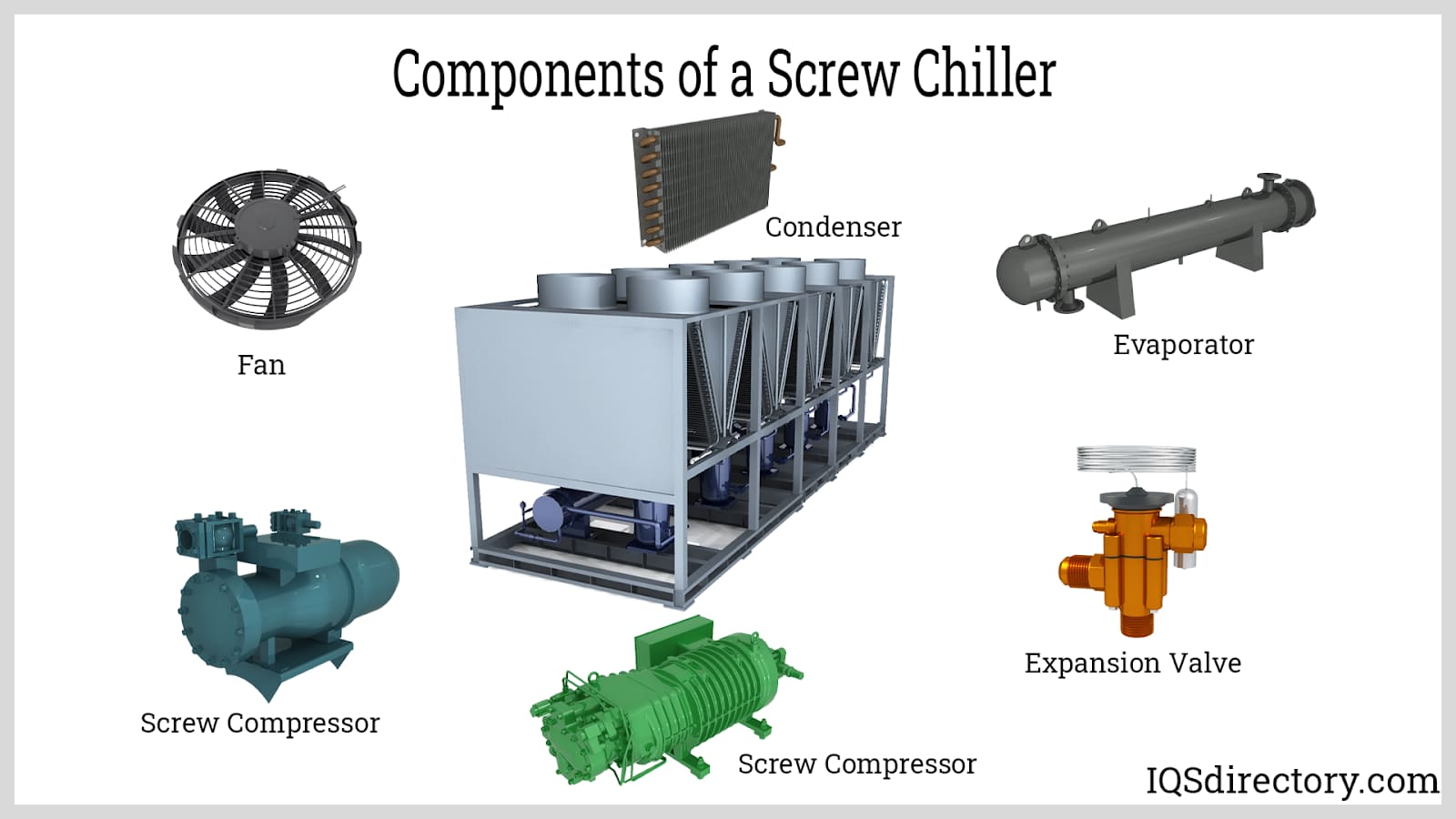

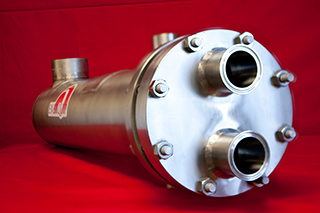

Screw chillers include a screw compressor, a condenser, evaporator, and expansion valve. As with all chillers, screw chillers can be air cooled or water cooled, depending on their design. Screw chillers are high-powered circulating chillers used in the chemical industry, printing, automobile manufacturing, and central air conditioning units.

Advantages of a Screw Chiller

The need for highly efficient and reliable cooling systems has risen due to technological advances and the need for energy-efficient cooling systems. Of the many industrial chillers on the market, screw chillers seem to be the preferred choice for industrial and commercial use.

Footprint

The main bulk component of chillers is the compressor, which can take up a great deal of space and require significant changes to a location during installation. However, screw chillers are compact, take up less space, and are easy to install.

Cooling

The most important quality of a screw chiller is how efficiently it cools a process or structure. Screw chillers operate and adjust according to the needs and capacity of the application without overcooling.

Energy Efficiency

A key factor for all implementations in modern society is energy use. Environmental concern has become a major issue that guides all manufacturers. Since screw chillers provide optimum cooling without overcooling, they consume less energy. The operation of screw compressors minimizes energy loss due to the design of the helical rotors and the tight seal on the compression cylinder.

Noise Level

Of the many characteristics of screw compressors, their lack of operating noise is one of their most significant and highly publicized. The smooth intermeshing of the rotors in the compressor housing does not create vibrations, which is the main source of noise for other chillers. This aspect of a screw chiller is a natural part of their function.

Maintenance

Screw chillers have a simple structure with fewer moving parts. The low ratio of moving parts makes it possible for screw chillers to operate for long periods without needing part replacement or maintenance. In addition, there is less wear on the various elements, which increases longevity and decreases the need for repair.

Types of Screw Chillers

The difference between screw and other compressors is that they provide a constant stream of compressed air without pulsating. The term screw chiller describes two types of compressors: single and twin screw. Due to their efficiency and reliability, screw chillers tend to be more expensive than other types of chillers, such as centrifugal and reciprocating. Of the two types, single screw chillers are less expensive and easier to maintain.

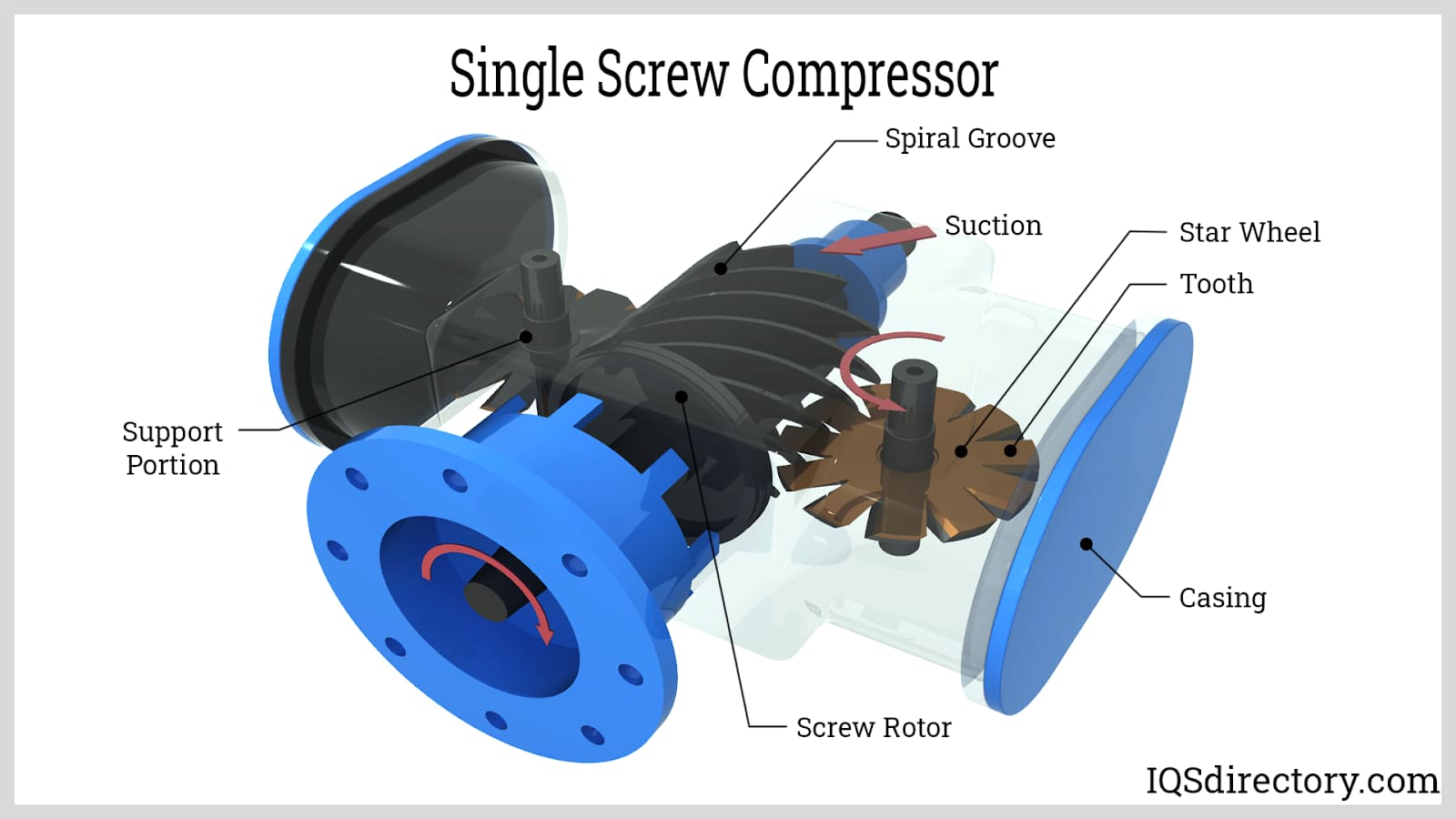

Single Screw Compressor

A single screw compressor gets its name from the single main rotor that rotates to activate the gate star wheels. Compression is produced by the rotation of the main rotor and occurs in the upper and lower halves of the compressor housing. The rotation of the main rotor pulls in the refrigerant. After the refrigerant is pressurized, it is discharged by one of the star wheels.

Single screw compressors are smaller and more compact but are highly efficient for small applications. Aside from being more appropriate for small applications, single screw compressors tend to have problems with wear on the star wheels.

Twin Screw Compressor

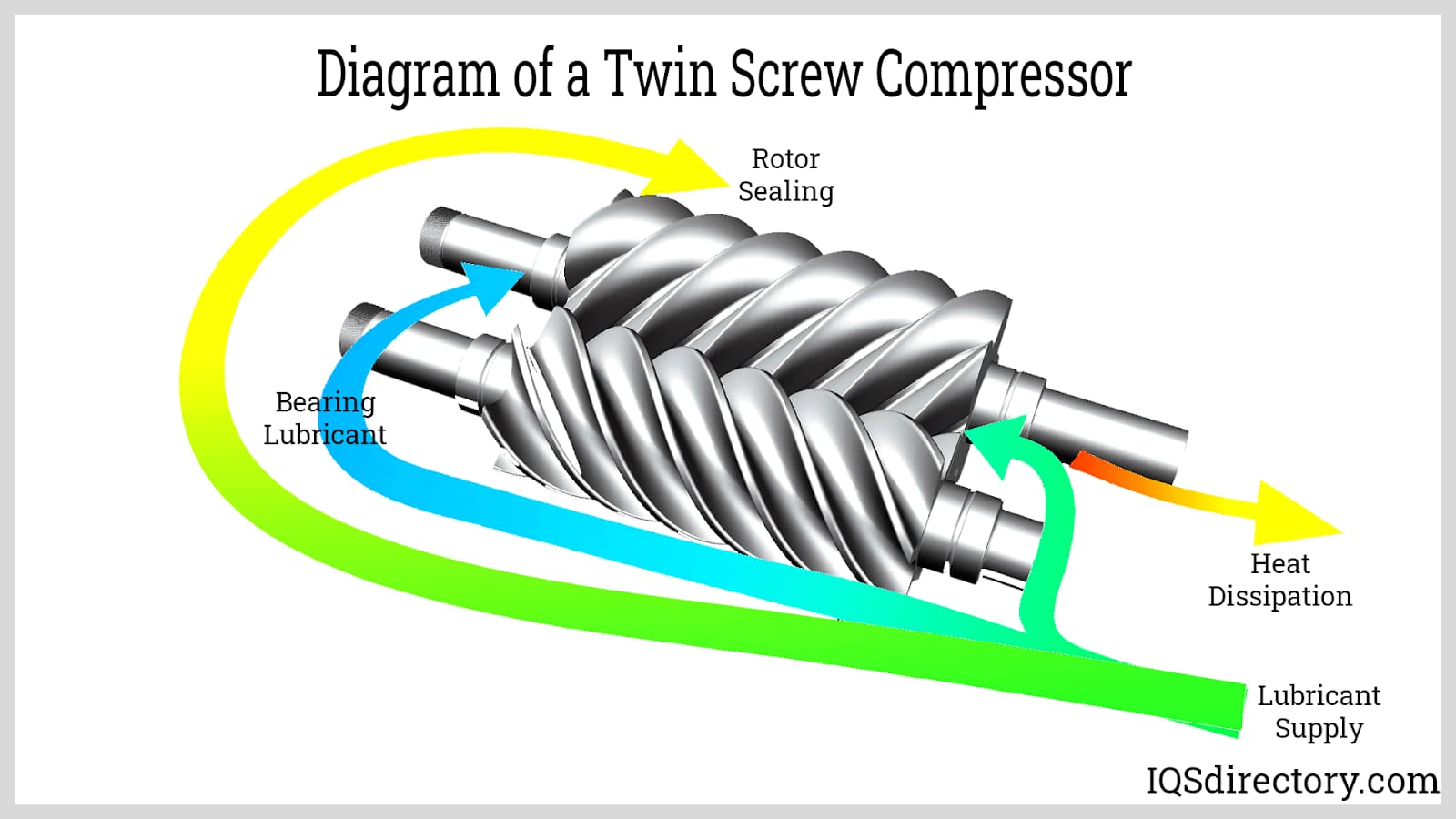

Twin screw compressors have two helical rotors attached to two shafts. One of the rotors is referred to as male, while the other rotor is referred to as female. The female rotor always has more flutes than the male. In the movement of the rotors, the male lobe acts like a continuous piston that rolls down into the female flutes that perform like a cylinder by trapping refrigerant and constantly reducing space to increase the pressure on the refrigerant.

As the refrigerant moves down the female rotor's grooves, its volume is reduced and compressed. When the male rotor lobe moves to the end of the groove, the compressed refrigerant gas is discharged out the outlet valve.

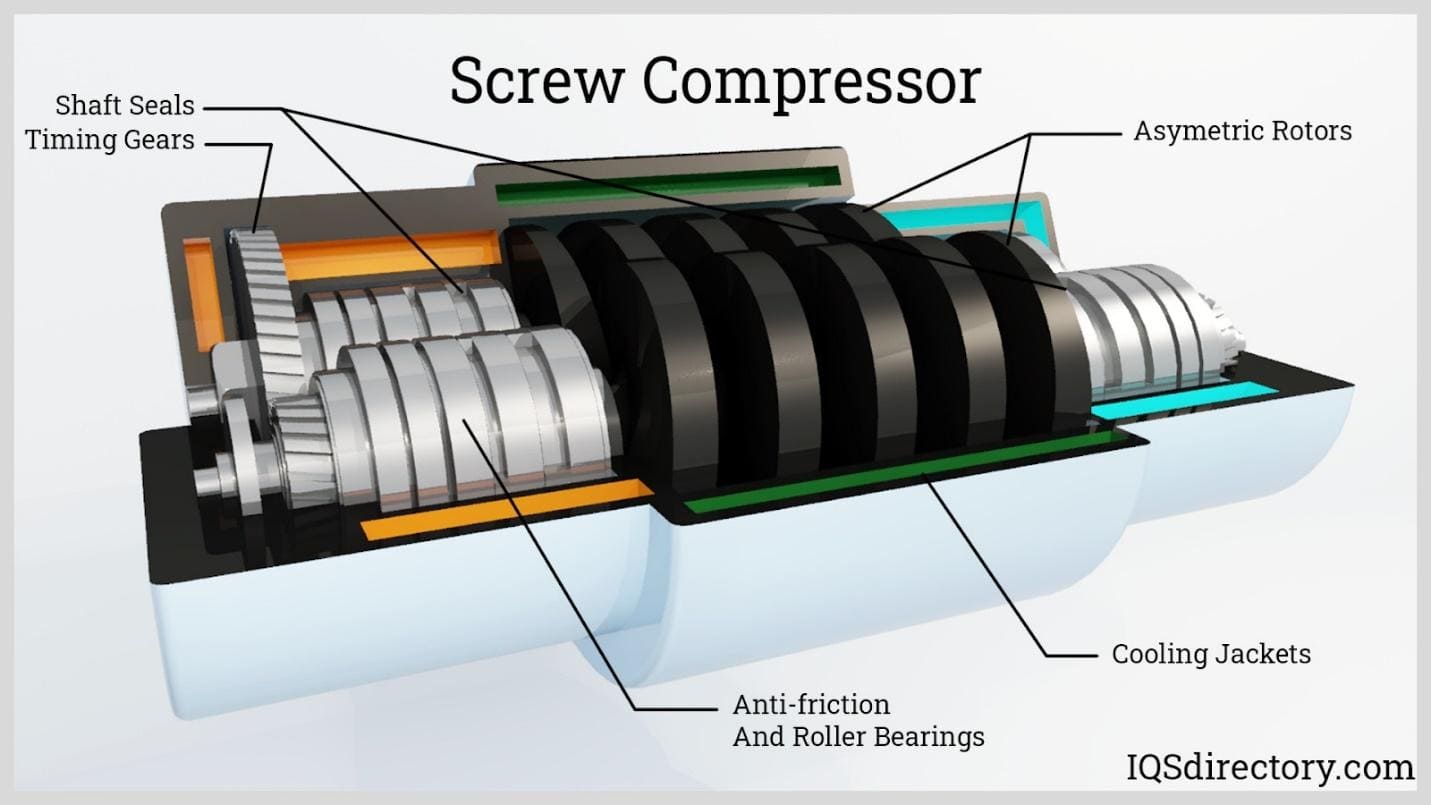

Parts of a Screw Chiller Compressor

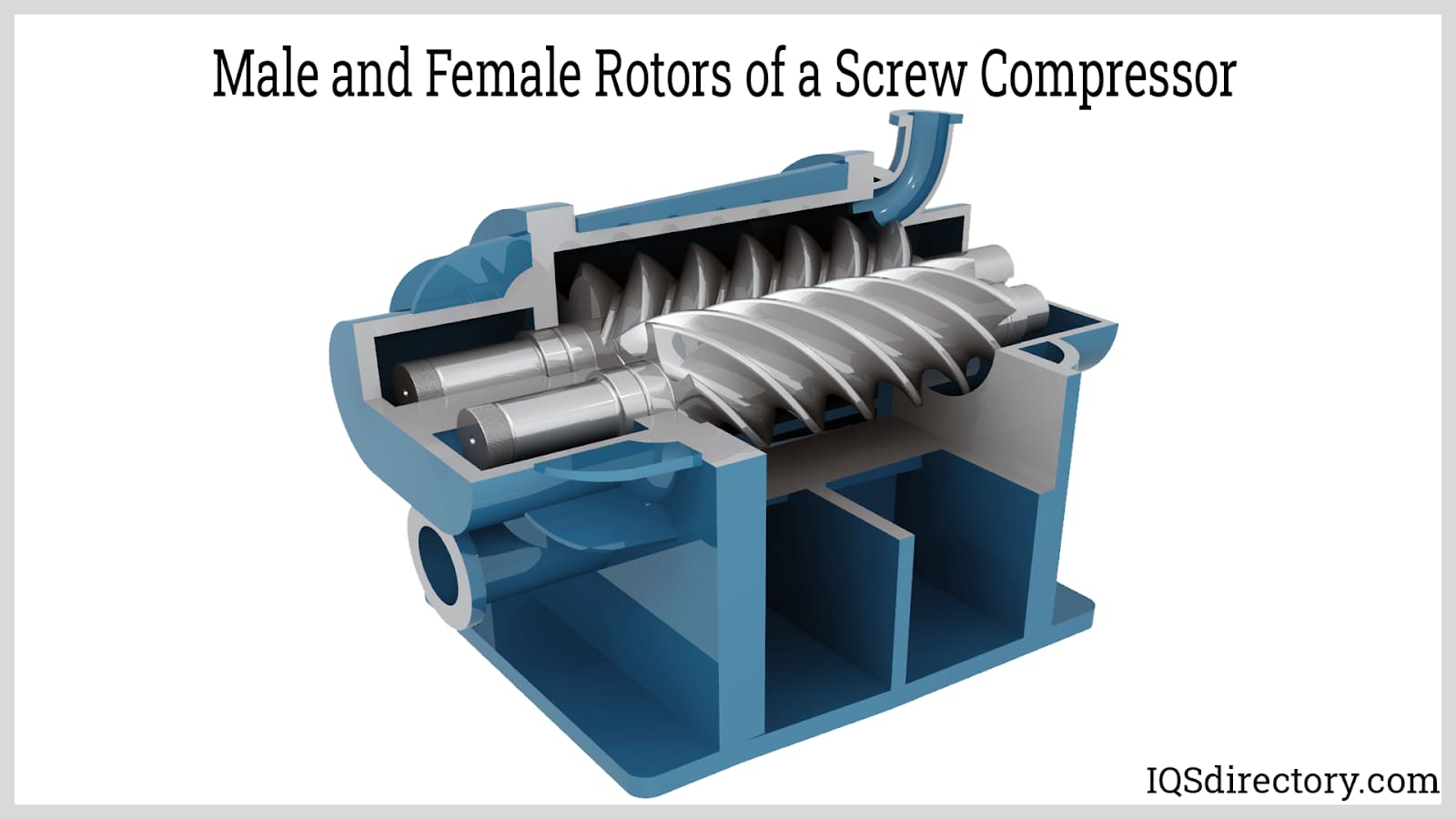

The structure of a screw chiller compressor includes four basic parts enclosed in a metal casing. Most screw chillers have two rotors that compress the refrigerant and play an important part in sucking in the refrigerant and discharging it.

Rotors

A screw compressor has two screws or rotors, one female and the other male. The male rotor is connected to a shaft driven by an electric motor. As the shaft rotates, the male rotor rotates and meshes with the female rotor. The meshing of the male and female rotors is essential to the operation of a screw compressor. As they rotate, they create suction and compression to pressurize the lubricant.

Compression Cylinder

When the rotors rotate, a vacuum is created in the compression cylinder, where the refrigerant enters through an inlet valve. If a compressor has one cylinder, it is referred to as a single-stage compressor. If there is more than one cylinder, the compressor is multistage.

Valves

The inlet and outlet valves allow the refrigerant gas in and discharge it. The refrigerant is drawn in through the inlet valve when a vacuum is created in the cylinder. As the rotors compress the gas and move it down the compression cylinder, the gas is discharged through the outlet valve.

Motor

An electric motor connected to the male rotor's shaft drives a screw compressor. The motor can be located inside or outside the screw compressor housing, depending on whether the compressor is semi-hermetic or open drive. Oil is used to lubricate the motor to help reduce its temperature. Some screw chillers use water to maintain the motor's temperature.

Choosing the RIght Screw Chiller Manufacturer

For the most productive outcome when purchasing a screw chiller from a screw chiller manufacturer, it is important to compare several companies using our directory of screw chiller manufacturers. Each screw chiller company has a business profile page that highlights their areas of expertise and capabilities, along with a contact form to directly communicate with them for more information or to request a quote. Review each screw chiller business website using our patented website previewer to get a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple screw chiller businesses with the same form.

Boilers

Boilers Chillers

Chillers Cooling Towers

Cooling Towers Furnaces

Furnaces Heat Exchangers

Heat Exchangers Heat Transfer Equipment

Heat Transfer Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services